The cook and hold process with food warmers has been around for over five decades in the restaurant industry as a way to keep food warm long in advance. But while conventional food warmers have gradually become better in recent years, most of them still have flaws. That biggest flaw was in maintaining temperature when the doors of the food warmer were opened to place new food inside. This potentially exposed the stored food to heat fluctuations and other unstable environments.

Yes, this might explain why some restaurants would occasionally get a complaint about something that wasn’t served as hot as it should have been. That’s assuming a restaurant invested in a food warmer rather than taking the worst chance of cooking food and having it sit around for too long before it was served.

With restaurants always looking for more efficiency, what can they do to improve the aging cook and hold process? Here at Thermodyne Foodservice Products, Inc., we offer food warmers with state-of-the-art technology that can essentially change the efficiency of your restaurant overnight.

What technology did we bring that allows cook and hold to evolve to near perfection?

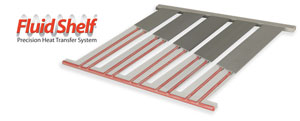

Fluid Shelf Technology as Game Changer

When we designed our patented Fluid Shelf Technology, we knew it would change the food warmer industry for the better. That’s because it uses a heat transfer process that helps keep every layer inside at a consistent temperature when the heat warmer door is consistently opened. Prior technology didn’t take into consideration that a food warmer door would be opened often to place new food inside. Prior technology such as perimeter heat sourcing and heating fans seem largely outdated now thanks to Fluid Shelf.

While that can save you and your restaurant team headaches in food preparation problems, what else can the basic cook and hold process do to save your restaurant money?

Saving Money on Energy and More Employees

Restaurant-Hospitality.com reminds how much the cook and hold process can save restaurants on their energy and labor costs. Because our food warmers use a slow cooking process, it requires less energy that saves you considerable money on your energy bill. If your restaurant ever used a conventional oven on a regular basis, you know how significant your energy bill was to your budget.

As well, you don’t have to worry about hiring extra help to prepare the food because things like meats can be unattended in the food warmers for days.

With these proven incentives, your restaurant needs to upgrade now if you’re still stuck using an outdated food warmer. Visit us here at Thermodyne to read more about the features our food warmers can bring you.

Contact us and we’ll also tell you about our food warmer variations. Many of them are used everywhere from institutional food service operators to governmental and military facilities.